Products

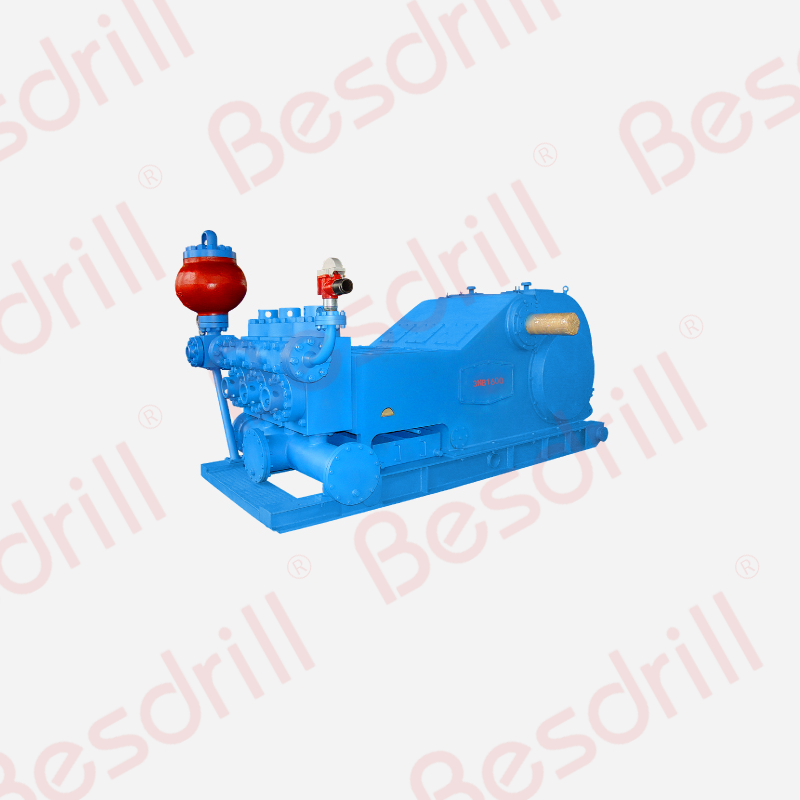

3NB1300

- Type:3NB Series

- CAS No:

- Qty in 20' FCL:

- Min. Order:

- Packaging:

-

Cylinder Diameter

mm

φ180

φ170

φ160

φ150

φ140

φ130

Discharge pressure

Mpa

18.4

20.7

23.4

26.6

30.5

34.5

Stroke

Input power

Output power

Discharge capacity (L/s)

Min-1

KW

Horse power

KW

Horse power

120

956

1300

860

1170

46.6

41.5

36.8

32.3

28.2

24.3

110

876

1191

789

1073

42.7

38.0

33.7

29.6

25.9

22.3

100

797

1083

717

975

38.8

34.5

30.6

26.9

23.5

2025

90

717

975

645

878

35.0

31.1

27.6

24.2

21.2

18.2

50

398.4

542

359

487.5

19.4

17.25

15.3

13.45

11.75

10.1

1

7.96

10.80

7.171

9.75

0.466

0.345

0.306

0.269

0.235

0.2025

( Mechanical efficiency 90%, coefficient of fullness α=100%, and volumetric efficiency 100% )

-

STRUCTURAL FEATURES OF RS-3NB1600/1300

Frame It is in structure of steel plate welding, the bearing block of transmission shaft and upper and bottom bases of

crank shaft are cast steel, the bearing block of crank adopts the structure of width plate and stiffened plate

reinforcement, and the rigidity is good and strength is high.

Crank shaft Casted by alloy steel.

Wheel set of transmission gear It is in involute herringbone gear, adopts medium hard tooth flank, and the drive

torque is high and the operation is smooth.

Pinion It is the forged by alloy steel, and either of two ends of transmission shaft can be installed with pulley.

Crosshead It adopts ductile iron cast and has the good antifriction performance. The guide plate adopts the structure

of upper and lower guide plates, which can adjust concentricity through adding washer at the lower guide plate.

Hydraulic cylinder It is the forged by alloy steel. It is in the form of straight-way type cylinder. The size of cylinder is

small, the volumetric efficiency is high, and the taper of valve seat hole is 1:6 and has steps. It is suitable for

operation under high pressure. The gland and flange on cylinder adopt the connection of saw tooth thread, and

flange is fastened on cylinder by bolts, which is convenient for speeding disassembly during service. The surface of

cylinder is treated by chemical nickel and phosphorus plating to enhance the performance of anti-corrosion.

Valve assembly NB1300 and NB1600 mud pumps adopt API 7# valve. The parts of hydraulic cylinder, cylinder,

plunger, valve, valve seat, valve spring, sealing part, valve cap and cylinder cap, etc. at the fluid end can be

interchanged.

Lubrication system Oil wiper and oil channel are installed at the position of pinion. The lube is delivered through oil

channel to the two bearings of transmission shaft and crank shaft and lubricating point on the top of guide plate. The

forced lubrication device can be matched on the outside of machine frame.