Products

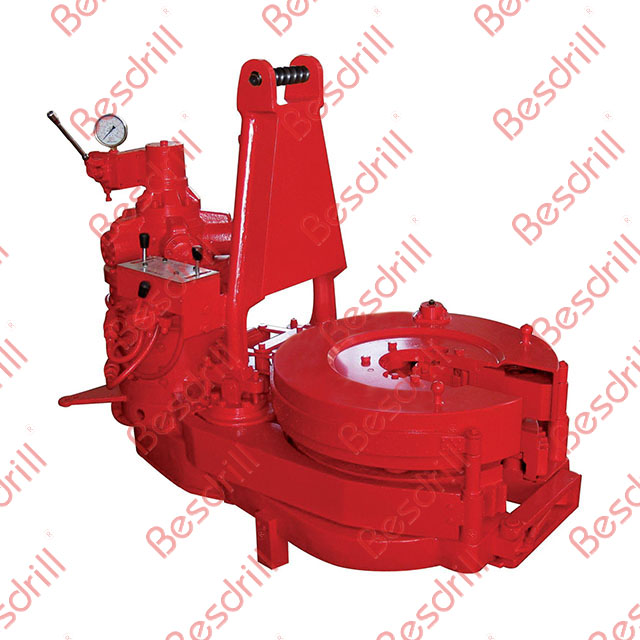

XQ 140 / 20 Micro- Tooth Marking, Non- Marking Hydraulic Power Tong

- Type:Power Tong

- CAS No:

- Qty in 20' FCL:

- Min. Order:

- Packaging:

-

1

Application Range

60~140 mm(23/8"~51/2")tubing, drill pipe joints, small casing

2

Torque Range

@ 1740psi / 12MPa

High gear:2.8 kN.m

Second high gear:6 kN.m

Second low gear:10kN.m

Low gear:21kN.m

3

Maximum RPM

@ 26.7 GPM / 100 LPM

High gear:51rpm

Second high gear:21rpm

Second low gear:14.5rpm

Low gear:6 rpm

4

Oil Flow

100 LPM @ 12 MPa / 26.7GPM @ 1740 psi

-

Characteristics:

Opening type,convenient and prompt to enter and slide off the working position,with an integral

tong head of great strength and rigidity.

Three-jaw-plate clamping device is adopted in the master tong and back tongs, which can

ensure minimum string damage. Front jaw of master tong is swing type,rear jaw is roller

climbing type, convenient to assemble and disassemble,the best design of diameter

ratio,ensure the reliable clamping, Three-jaw-plate structure is adopted in the master tong and

back tongs,this structure is hydraulic cylinder pushing and clamping style,it can clamp the body

of the tubular,and also can clamp the coupling,with simple structure and reliable clamping.

Only needs to change the Hardware alloy coating die(low stress point-like mark left on the

tubular column,no straight strip tooth mark,No tooth mark die for short.it is recommended to use

on 3Cr、9Cr、13Cr、22Cr、25Cr tubing and casing or fine tooth die(tiny straight strip tooth

Mark left on the tubular column, Micro tooth mark die for short.).

Four-gear rotation is adopted for large speed regulation range,and the rated torque is large.

Safety door interlock device is adopted, when the safety door is open,the tong head will not

revolve,it is safe and reliable.

The overall frame structure is adopted in the master tong and back tong,floating connection of the

backup tong,distance between the master tong and backup tong can be adjusted,damage can be

reduced to the tubular column in make up and break out operation.

To be used along with double pump hydraulic power station,it can realize a rotate speed of

20 ~ 25rpm when make up in the beginning,then fastening at a speed of 1~6rpm after reaching

the shouldering torque.

To be used along with torque and rotational speed test system and double pump hydraulic

power station can precisely control the make up torque and rotation speed,it can display、control

storage、print torque parameters and etc.,and it can apply to the make up of FOX、VAM TOP

BGT1、3SB、NSCC、WSP type of tubing and casing.