Products

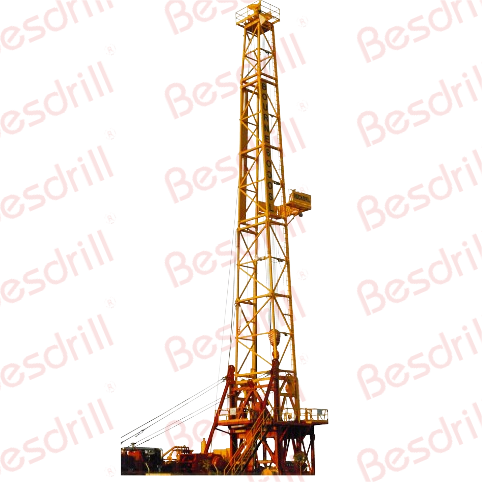

THD35(hydraulic top-head drive drill)

- Type:Own Rig

- CAS No:

- Qty in 20' FCL:

- Min. Order:

- Packaging:

-

THD35

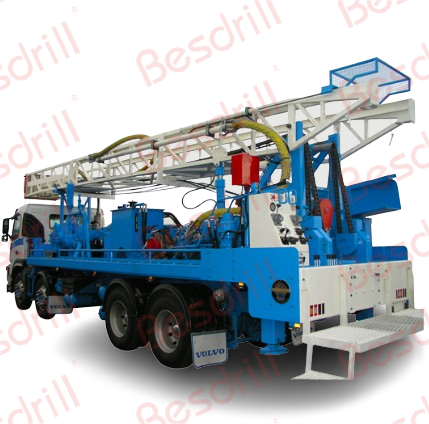

Truck Mounted Rig

Ideal for

Foundations

Mineral Exploration

Water Wells

CATEGORY HYDRAULIC TOP HEAD DRIVE

-

The key characteristics of the THD35 drilling rig are as follows:

1. Mounting: The THD35 drilling rig is truck-mounted, providing mobility and ease of transportation to various job sites.

2. Versatility in Applications: Ideal for foundations, mineral exploration, and water wells, the THD35 is suitable for a wide range of drilling operations across different industries.

3. Pullback Capacity: The rig has a rated pullback capacity ranging from no less than 16,000 kg (35,270 lbs) to no less than 34,090 kg (75,155 lbs), providing substantial force for efficient drilling operations.

4. Drilling Methods: Designed primarily for mud rotary drilling, the rig also supports limited air blast and D.T.H hammer drilling when fitted with suitable options. This versatility allows for adaptation to various geological formations and project requirements.

5. Drilling Specifications:

- Hole Size: Ranging from 203mm (8") to a depth of 457m (1500 ft).

- Pulldown Force: 25,000 kg (55,000 lb).

- Pullback Force: 25,000 kg (55,000 lb).

- Variable Head Speeds: Ranging from 0 to 60 RPM and 0 to 120 RPM, with corresponding torque ratings.

- Winch Capacity: Options available for 8000 kg or 10000 kg winch capacity.

- Mud Pump Options: Available in sizes of 5-1/2 x 8 or 7-1/2 x 8.

6. Adaptability and Customization: The THD35 can be fitted with suitable options such as different drilling tools, winch capacities, and mud pump sizes to enhance its functionality and meet specific drilling requirements.

Overall, the THD35 drilling rig offers robust pullback capacity, versatility in drilling methods, and adaptability to various drilling applications, making it well-suited for foundation drilling, mineral exploration, and water well projects.

- "Hydraulic top-head drive drills" refers to drills that utilize a hydraulic top-head drive system. These drills employ hydraulic pressure to drive the main power head located at the top of the drill, enabling the rotation of the drill bit for drilling operations. Hydraulic top-head drive drills are widely used in various fields such as geological exploration, water well drilling, and foundation engineering. These drills are typically designed to be mobile, allowing for easy installation on trucks, excavators, or other vehicles, facilitating drilling operations at different locations. Due to their efficient hydraulic drive system providing effective power transmission and precise control, hydraulic top-head drive drills are extensively utilized in various drilling applications.

- Our company Besdrill has always had close cooperation with Bourndrill, and many of our products are our competitive advantages. Please feel free to select the products you like.