Products

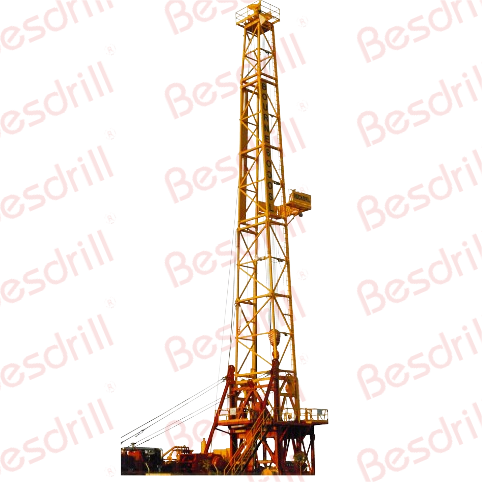

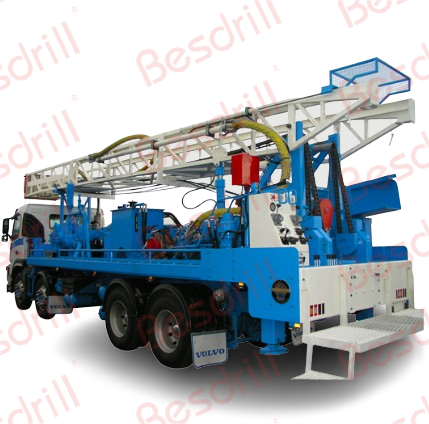

500RC(Reverse Circulation Drill Rig)

- Type:Own Rig

- CAS No:

- Qty in 20' FCL:

- Min. Order:

- Packaging:

-

500RC

Ideal for Drilling Water Wells

CATEGORY REVERSE CALCULATION

-

The advantages of using reverse circulation in water well drilling machines include:

-

Improved drilling efficiency: Reverse circulation drilling technology can increase drilling speed because during this process, drilling fluid can quickly carry cuttings out of the wellbore, reducing return time and resistance, thereby improving drilling efficiency.

-

Reduced drilling costs: Reverse circulation technology can reduce the usage and treatment costs of drilling fluid. Since cuttings are carried out underground, the amount of drilling fluid returning to the surface is reduced, saving a significant amount of drilling fluid and related treatment costs.

-

Less formation damage: Reverse circulation drilling can reduce interference with formations during drilling, reducing the degree of formation damage. By more effectively removing cuttings, the risk of formation collapse and loss during drilling can be reduced.

-

Improved wellbore stability: Reverse circulation technology can enhance the stability of the wellbore, reducing the risk of wellbore collapse and hole instability due to cuttings accumulation. This helps ensure smooth drilling operations and reduces the potential for accidents and delays.

-

Enhanced safety: Reverse circulation technology can improve the safety of drilling operations. By more effectively controlling bottom hole pressure and removing cuttings, the probability of accidents and incidents can be reduced, ensuring the safety of personnel and equipment.

-

-

"Reverse Circulation Drill Rig" is a specific type of drilling rig that operates on the principle of reverse circulation. In traditional drilling processes, drilling fluid flows from the bottom of the drill bit to the wellhead, and then the drilling fluid is discharged from the wellhead through the drill pipe. However, in a reverse circulation drill rig, the flow direction of the drilling fluid is reversed compared to traditional drilling; it flows from the bottom of the well towards the wellhead, and then the drilling fluid is discharged from the wellhead through pipes.

The advantages of using reverse circulation in water well drilling machines include:

-

Improved drilling efficiency: Reverse circulation drilling technology can increase drilling speed because during this process, drilling fluid can quickly carry cuttings out of the wellbore, reducing return time and resistance, thereby improving drilling efficiency.

-

Reduced drilling costs: Reverse circulation technology can reduce the usage and treatment costs of drilling fluid. Since cuttings are carried out underground, the amount of drilling fluid returning to the surface is reduced, saving a significant amount of drilling fluid and related treatment costs.

-

Less formation damage: Reverse circulation drilling can reduce interference with formations during drilling, reducing the degree of formation damage. By more effectively removing cuttings, the risk of formation collapse and loss during drilling can be reduced.

-

Improved wellbore stability: Reverse circulation technology can enhance the stability of the wellbore, reducing the risk of wellbore collapse and hole instability due to cuttings accumulation. This helps ensure smooth drilling operations and reduces the potential for accidents and delays.

-

Enhanced safety: Reverse circulation technology can improve the safety of drilling operations. By more effectively controlling bottom hole pressure and removing cuttings, the probability of accidents and incidents can be reduced, ensuring the safety of personnel and equipment.

-

- Our company Besdrill has always had close cooperation with Bourndrill, and many of our products are our competitive advantages. Please feel free to select the products you like.